Alan Rogers was the backbone of the shop at RTC for

twenty-five years. If you had him as a teacher, you never forgot him.

If he made you build a butter caddy, you definitely never forgot that.

“Cabinetmaking is a

discipline,” he liked to say, and nothing said discipline like the fiendish little butter caddy.

Producing it pushed the limits of student ingenuity with

router jigs. The most possible learning from the least possible material, Alan maintained. Every step required constant attention to cutter rotation, grain

direction, and control of the stock. Many a caddy was shattered by a careless feed rate! The project embodied Alan’s ideals: respect for the material, precise set-ups, deep focus during operation.

So when Alan retired in 2019, his colleagues decided to send him off with a butter caddy of his own. We scaled it up to the size of a two-seat bench and gave it legs.

The change in scale brought a few changes

in construction methods (including some CNC) but true to Alan’s spirit, everything was built using wood at

EMC, sharp cutters, nifty jigs, and... well, actually lots of abrasives in the end.

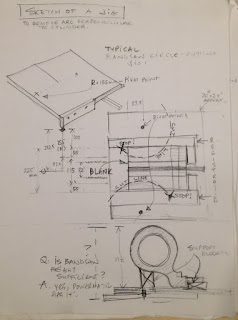

The mock-up:

Jig for cutting away the arcs

Clamping jigs

Ready to leave the shop...

Butter-pat cushions: the final

touch!

Fabulisimus!!!!!

ReplyDeleteAbsolutely love this! You look so happy dad!

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteWhat a brilliant tribute! The craftsmanship reminds me of the attention to detail we saw when upgrading with custom garage cabinets recently—precise, well thought out, and built to last. Alan’s legacy clearly lives on.

ReplyDelete